Tel: +86 15051225801

Email: [email protected]

Tel: +86 15051225801

Email: [email protected]

Quick Detail:

1. Different names of products:

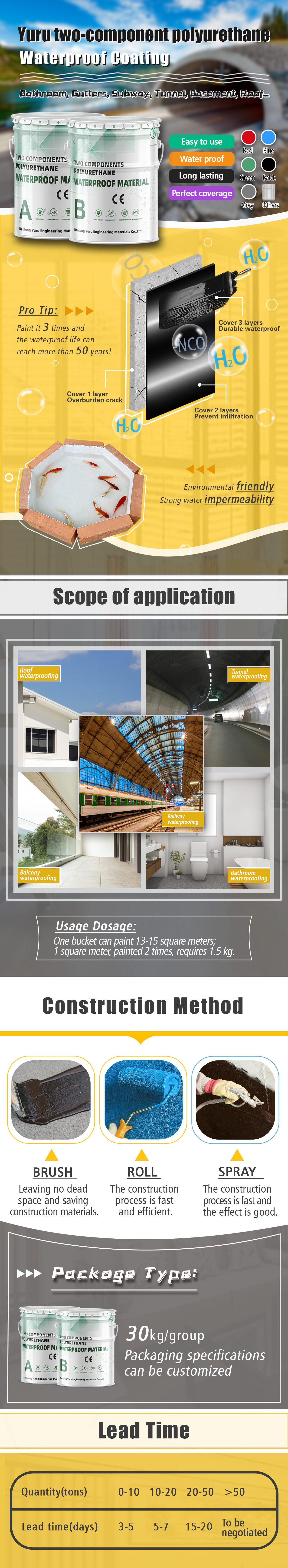

Two components polyurethane waterproof material/Two-component polyurethane waterproof paint/911polyurethane waterproof coating

2. Main uses:

It is suitable for waterproofing and anti-seepage in underground projects (concrete interior walls, floors, tunnels, etc.) and toilets, bathrooms, kitchens, exterior walls, roofs, etc., and for bonding and sealing cement boards, expansion joints, construction joints, etc.

| Place of Origin: | Nantong, Jiangsu, China |

| Brand Name: | Yuru |

| Model Number: | YR-P103 |

| Certification: | CE |

| Minimum Order Quantity: | 100 kilograms |

| Price: | / |

| Packaging Details: | 30kg/group |

| Packaging specifications can be customized | |

| Delivery Time: | 7-15days |

| Payment Terms: | T/T, L/C,paypal, western union |

| Supply Ability: | 1000 tons per month |

Description:

Multiple groups of polyurethane waterproof coating is a multi group divided reaction curing type polymer waterproof coating, were obtained by condensation polymerization reaction of isocyanate and polyether polyurethane pre polymer and plasticizer, curing agent, thickening agent, accelerator, filler consisting of multiple solution. Make when the groups divided according to a certain proportion, mixing evenly, brushing in need of construction on the surface of the base layer, the curing reaction formation elastic, tough and durable waterproof coating.

Features:

◇Waterproof coating film elongation rate, high strength, good elasticity;

◇Film dense, no bubbles, no pinhole;

◇Cold construction, convenient construction;

◇Corrosion resistance, acid, alkali, salt and other chemical components;

◇Surface adhesion strong, not strong permeability;

Applications:

◇Non exposed roofing;

◇Underground waterproof: basement floor, side wall, nurse wall, tunnel;

◇Other: roof, toilet, kitchen, balcony, water pool, wall pipe, water outlet.

Specifications:

| Item | Project | Index |

| 1 | Solid content(%) | 98 |

| 2 | Surface drying time/h | 8 |

| 3 | Fully drying time/h | 11 |

| 4 | Tensile strength/MPa | 3.9 |

| 5 | Elongation at break/% | 800 |

| 6 | Low temperature flexibility | -35℃,No crack |

| 7 | Water impermeability | 0.3MPa,120min,Impervious |

| 8 | Bonding strength/Mpa | 1.8 |

| 9 | Tear strength/(N/mm) | 25 |

Competitive Advantage:

1. Long service life: it can last for more than 50 years after three coats of painting.

2. Good waterproof performance: The two-component polyurethane waterproof coating can form a dense waterproof film, which can effectively prevent water penetration.

3. Corrosion resistance: The two-component polyurethane waterproof coating has good acid, alkali, grease and other chemical corrosion properties, and can effectively prevent erosion by external chemical substances.

4. Weather resistance: The two-component polyurethane waterproof coating has good weather resistance and can be used in outdoor environments for a long time without aging or cracking.

5. High construction efficiency: The construction process of two-component polyurethane waterproof coating is simple, fast and pollution-free, which can greatly improve construction efficiency.

01 Key points of construction:

◇Basic requirements: flat, strong, fully dry;

◇Ingredients: according to the amount of construction, the proportion of each component is mixed, stir evenly;

◇Waterproof construction of large area: hybrid coatings with rubber or plastic scraper, uniform coating, uniform thickness, usually 1.5mm-2.0mm, ought to be divided into 3-4 times brushing, brushing after the meeting should be in the previous besmear brushs curing film, and is perpendicular to the direction of scraping.

◇Header and edge processing: the coating is closed.

◇Protection layer: the waterproof layer of the film should be designed to protect the surface according to the design requirements, to prevent damage to the film waterproof layer.

02Matters need attention

◇The construction site should be ventilated, rainy days can not be construction;

◇Waterproof coating to be used at the site with the use, with a good material must be used up before solidification, has been cured of the mixture can not be diluted and then.

◇Before the film is not working, it is strictly prohibited to walk on the waterproof layer, and pay attention to the protection is not damaged.

◇Construction site should pay attention to fire.

Storage and transportation:

◇Stored in a dry room, away from the fire source, heat source.

◇The collision and during transport to prevent the sun and rain.

Reference dosage:For each millimeter thick film, coating dosage weight is about 2.2kg/㎡-2.5kg/㎡.

Copyright © Nantong Yuru Engineering Materials Co., Ltd. All Rights Reserved