Tel: +86 15051225801

Email: [email protected]

Tel: +86 15051225801

Email: [email protected]

Quick Detail:

1. Different names of products:

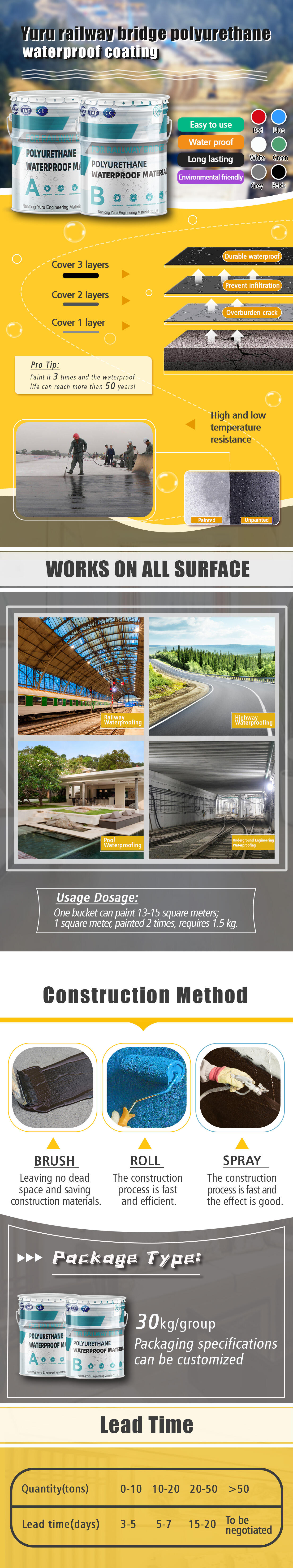

Polyurethane waterproof coating for railway bridges /Polyurethane waterproof material for railway bridges

2. Main uses:

It is suitable for waterproofing and anti-seepage of railway bridges with ballast and ballastless concrete bridge decks, as well as waterproofing projects such as highway concrete bridge decks and water conservancy dams; used for pasting membranes and polyurethane waterproof coatings directly used as waterproof layers.

| Place of Origin: | Nantong, Jiangsu, China |

| Brand Name: | Yuru |

| Model Number: | YR-P104 |

| Certification: | CE |

| Minimum Order Quantity: | 100 kilograms |

| Price: | / |

| Packaging Details: | 30kg/group |

| Packaging specifications can be customized | |

| Delivery Time: | 7-15days |

| Payment Terms: | T/T, L/C,paypal, western union |

| Supply Ability: | 1000 tons per month |

Description:

Polyurethane waterproof coating for railway bridges (for high-speed rail) is a two-component chemical reaction waterproof coating. Component A is an isocyanate-terminated prepolymer obtained by polycondensation of polyether and isocyanate. Component B is composed of reinforcing agent and plasticizer. Colored liquid composed of agents, thickeners and coagulants. When using, mix components A and B evenly in proportion, apply them on the waterproof base layer, and cross-link and solidify at high temperatures to form a rubber-like elastic coating film with high strength and high elongation.

Features:

◇High strength, up to 6.0MPa or more; good elongation performance and excellent low temperature performance.

◇The product can be applied thickly, and the coating film is dense and bubble-free to form a continuous and seamless elastic waterproof layer.

◇Cold construction, construction can be carried out after components A and B are fully mixed in proportion, and the operation is simple.

◇Chemical reaction film formation, corrosion resistance, mildew resistance, low temperature resistance, and strong water impermeability.

Applications:

Waterproof and moisture-proof projects such as high-speed railways, viaducts, highways, underground projects, municipal projects, pools, dams, etc.;

Used to paste waterproof membrane or directly used as waterproof layer;

It can also be used for anti-corrosion treatment of metal equipment, pipelines, wooden boats, etc.

Specifications:

| Item | Project | Index |

| 1 | Surface drying time/h≤ | 4 |

| 2 | Fully drying time/h≤ | 24 |

| 3 | Tensile strength/MPa≥ | 6 |

| 4 | Elongation at break/%≥ | 450 |

| 5 | Tear strength/(N/mm)≥ | 35 |

| 6 | Low temperature bendability | -35℃, no cracks |

Competitive Advantage:

1. Long service life: it can last for more than 50 years after three coats of painting.

2. Strong weather resistance: Railway bridge polyurethane waterproof coating has good weather resistance, can maintain stable performance for a long time under various climate conditions, and is not easy to age, crack or fall off.

3. Good chemical corrosion resistance: PU coating has good chemical corrosion resistance and can resist the erosion of chemical substances such as acids, alkalis, and salts, and protect road and bridge structures from corrosion.

4. Good bonding performance: Railway bridge polyurethane waterproof coating can firmly bond with the base material to form a strong waterproof layer, effectively preventing moisture penetration.

5. High elasticity and flexibility: Railway bridge polyurethane waterproof coating has high elasticity and flexibility, high tensile strength, large elongation, strong resistance to base deformation, and can adapt to the deformation and vibration of the road and bridge structure, and is not easy to Cracked or broken.

6. Convenient construction: Railway bridge polyurethane waterproof coating is easy to construct and can be constructed by brushing, spraying, rolling, etc. The curing time is short and a waterproof layer can be quickly formed.、

01 Key points of construction:

◇The base layer must be solid, flat, free of debris, and fully dry.

◇Ingredients should be mixed according to the proportion of the two components A and B according to the construction dosage, and stirred evenly with an electric stirring rod. Additional treatment should be done on the node parts as required.

◇The construction uses scraping or spraying, and the thickness is required to be uniform. The thickness is generally 1.5mm-2.5mm, and should be completed in 3-4 passes. The subsequent coating should be done after the previous coating is cured, and the direction of brushing or spraying should be perpendicular to the previous coating.

◇After the acceptance of the coating film, the protective isolation layer shall be constructed according to the design requirements.

02Matters need attention:

◇Limited to use in rain, snow, wind and sand, and low temperature weather.

◇If there is precipitation in component B, it will not affect the quality of the product. When using it, stir it evenly and then mix it with component A in proportion.

◇Fireworks are strictly prohibited at the construction site.

◇After the acceptance of the coating film, the protective layer should be constructed in time.

Storage and transportation:

Store materials in a dry and ventilated room. During transportation, be careful not to be exposed to the sun or rain, prevent collisions, and pay attention to fire prevention. The product storage period is one year. It can only be used after passing the re-inspection after the storage period.

Reference dosage:For each millimeter thick film, coating dosage weight is about 2.2kg/㎡-2.6kg/㎡.

Copyright © Nantong Yuru Engineering Materials Co., Ltd. All Rights Reserved