Tel: +86 15051225801

Email: [email protected]

Tel: +86 15051225801

Email: [email protected]

Concrete structures are not immune to cracking, they are sturdy and resistant to weathering. If you don't fix these fractures, you can end up with serious structural damage that can damage buildings, bridges, roads, etc. Yuru polyurethane grout injection for waterproofing is the most reliable and precise of all the repair techniques. This paper covers the specifics of this method, its significance, modern uses, sustainable alternatives, and the scientific basis for its effectiveness.

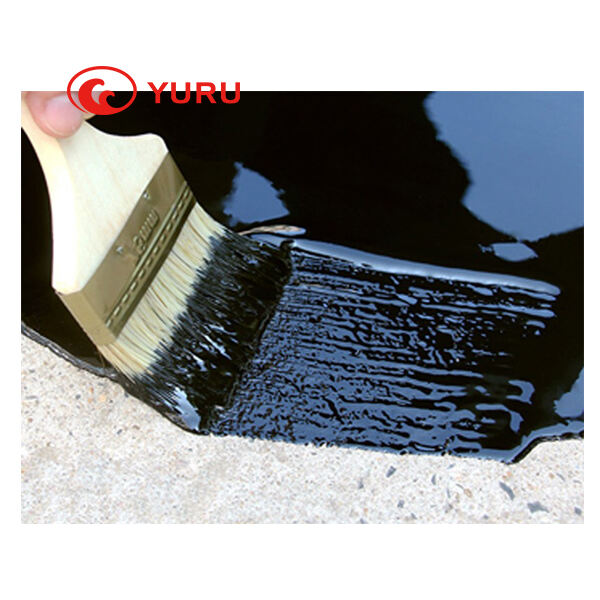

Injection grouting penetrates cracks and seals them from the inside out, that’s the key to its effectiveness grouting restores monolithic concrete, unlike surface level patching that only covers the gaps. This prevents water from engrossing into space and causing further expansion due to freeze-thaw cycles, resulting in a lasting repair. Yuru epoxy grout repair, such as epoxy, polyurethane, or cementations, can restore or enhance the original strength of the damaged area.

Injection grouting has advanced beyond the traditional methods of infrastructure restoration. Specialized equipment can force grout into cracks that are too small to access using advanced technologies, resulting in pressurized injection. Yuru two part epoxy grout is guaranteed and active leaks can be fixed at high hydrostatic pressure and can be filled with water. Micro injections are becoming more popular, allowing for minimal disturbance to surrounding structures during repairs on delicate heritage buildings or in confined spaces.

Sustainability is not just about building and maintenance anymore. Crack repair is getting more popular with environmentally friendly injection grouting solutions envelopment greener options not only reduces the carbon footprint but also creates safer working environments for technicians and leads to a healthier indoor environment after the repair with Yuru pu grouting waterproofing.

Copyright © Nantong Yuru Engineering Materials Co., Ltd. All Rights Reserved