Tel: +86 15051225801

Email: [email protected]

Tel: +86 15051225801

Email: [email protected]

Quick Detail:

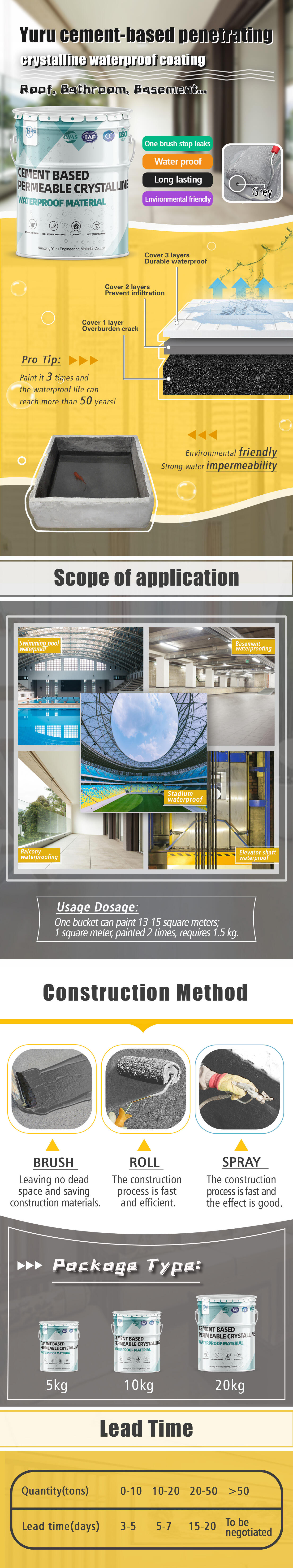

1. Different names of products:

Capillary/Crystalline Waterproofing Materials;CCCW waterproof coating;Cement-based waterproof

coating

2. Main uses:

It is used for waterproofing construction of tunnels, underground diaphragm walls, cable tunnels,

underground culverts, industrial and civil building basements, underground garages, bathrooms,

reservoirs, pools, swimming pools, elevator shafts and other new projects. Plugging construction of

structural cracks (micro-cracks), water seepage points, and holes, and repairing defects in concrete

facilities. Anti-corrosion of concrete structures and cement mortars.

| Place of Origin: | Nantong, Jiangsu, China |

| Brand Name: | Yuru |

| Model Number: | YR-CW302 |

| Certification: | CE |

| Minimum Order Quantity: | 100 kilograms |

| Price: | / |

| Packaging Details: | 25kg/barrel |

| Packaging specifications can be customized | |

| Delivery Time: | 7-15days |

| Payment Terms: | T/T, L/C,paypal, western union |

| Supply Ability: | 1000 tons per month |

Description:

The silicone ions dissolved in the CCCW cement-based penetrating crystalline waterproof coating penetrate and diffuse in the concrete with the surface water, and chemically react with the calcium ions in the concrete to form water-insoluble calcium silicate hydrate (dendritic crystal). The crystals fill the capillary pores and combine with the concrete to form a whole, blocking the capillary channels inside the concrete, thereby making the concrete dense and preventing water leakage. Moreover, CCCW has catalytic properties. Once it encounters water, it can continuously produce chemical reactions. The generated crystals continue to grow and fill the capillary pores inside the concrete. Therefore, even if the concrete structure is partially damaged and leaks, crystallization will occur when it encounters water. It can repair and heal (0.4mm cracks) by itself.

Features:

◇Can be constructed on the front and back surfaces of concrete structures.

◇Especially suitable for construction on wet base surfaces.

◇Long-lasting activity, capable of naturally healing fine cracks below 0.4mm.

◇Because of its special permeability, there is no need to set up a protective layer after construction.

◇Enhance the strength of concrete structures and prevent damage to concrete caused by freeze-thaw cycles.

◇Protect steel bars and prevent steel bars from rusting.

◇Harmless and can be used on concrete structures for drinking water.

◇Easy to use, easy to

operate, no construction joints.

◇Protect concrete structures from wastewater, seawater, chemicals and solvents.

Applications:

It is suitable for waterproofing and anti-seepage treatment of swimming pools, drinking water pools, sewage pools, marine aquariums, dams, reservoirs and other storage pools.

It is suitable for waterproofing and anti-seepage in basements, underground sewers, elevator shafts, balconies, bathrooms and other water-immersed environments.

It is suitable for waterproofing projects in roads, bridges, tunnels, stadiums, nuclear power plants, military facilities, municipal projects and pile head treatment.

Specifications:

| Item | Project | Performance index | |

| 1 | Rate of water content/%≤ | 1.5 | |

| 2 | Finenes,0.63mm residue on sieve/%≤ | 5 | |

| 3 | Construction property | After adding water and stirring | Scrape and coat without obstacle |

| 20min | Scrape and coat without obstacle | ||

| 4 | The wet surface adhesion strength/MPa,28d≥ | 1.0 | |

| 5 | Mortar Penetration resistance | Infiltration pressure ratio (with coating)(28d),% ≥ | 250 |

| Infiltration pressure ratio (removal of coating) (28d),%≥ | 175 | ||

Competitive Advantage:

1. Long service life. After painting 3 times, the service life can reach more than 30 years.

2. Has double waterproof performance

The penetrating crystals produced by cement-based penetrating crystalline waterproofing materials can penetrate deep into the concrete structure and block the structural pores. Regardless of the penetration depth, it can play a waterproofing role inside the structural layer; at the same time, the coating acting on the base surface of the concrete structure due to Its micro-expansion performance can compensate for shrinkage and make the structural base surface after construction also have good anti-cracking and anti-seepage effects.

3. Have strong ability to withstand pressure

It has extremely strong pressure resistance, up to 3.0MPa. The waterproof layer and the concrete surface form a complete system and will not separate. The material can fully absorb the moisture on the concrete surface to participate in its crystallization reaction, and no hollowing will occur.

4. Has unique self-healing ability

Cement-based permeable crystalline waterproofing material (CCCW) has catalytic properties. Once it encounters water, it can continuously produce chemical reactions. The generated crystals continue to grow and fill the capillary pores inside the concrete. Therefore, even if the concrete structure is partially damaged and leaks, it will not leak when encountering water. After being exposed to water, it will also produce crystallization and repair itself (0.4mm cracks).

5. It has the functions of anti-corrosion, aging resistance and protection of steel bars.

Chemical attack of concrete and corrosion of steel bars are inseparable from the penetration of moisture and chloride ions. The penetrating crystallization and self-healing capabilities of cement-based penetrating crystalline waterproofing materials make the concrete structure dense, thereby minimizing the intrusion of chemicals, ions and moisture and protecting reinforced concrete from erosion.

The water-insoluble crystals produced by cement-based penetrating crystalline waterproofing materials do not affect the ability of concrete to breathe, and can maintain normal ventilation, moisture removal, and dryness inside the concrete structure. It also extends the length of the building while keeping the steel bars inside the concrete from being eroded. service life.

6. It has a reinforcing effect on concrete structures.

The structure after construction with cement-based penetrating crystalline waterproofing materials is not a reactivation of the crystal structure, but activation of unhydrated cement, which increases the density and strengthens the structure. Generally, it can increase the strength of concrete by 20%. ~30%.

7.It has long-term waterproofing effect, complies with environmental protection standards, is non-toxic and pollution-free, has simple construction methods and saves labor and time.

01 Construction points:

◇Scraping method:

Clean the debris and floating mud mortar on the waterproof coating base surface, and repair the severely uneven concrete base surface.

Eradicate and clean the oil stains and debris on the waterproof surface of the cement-based concrete structure, then rinse with clean water, and apply waterproof materials on the wet base surface.

If serious leakage is found on the base surface, leak-stopping materials should be used for construction first, and then this material can be used to ensure the quality of the project.

◇Roller coating method:

Roll the material evenly onto the treated base surface.

◇Dry spreading method:

Construction is carried out immediately after the concrete is poured, compacted and leveled. Sprinkle the specified amount evenly on the concrete surface, compact and smooth in time. After final setting, check whether there are any bad construction areas and repair them in time.

In case of exposure to the sun, water should be sprayed for maintenance. Pay attention to spray evenly.

02 Matters need attention:

◇Normal temperature construction, should not be below zero degrees Celsius and rain, fog, sand and other harsh conditions under construction;

◇Mix the material water, conserve water to drink water for the best, should not use clean water

◇Construction must be carried out in the concrete structure or solid cement mortar base surface. Do not apply directly to the fly ash layer surface, surface should be clean and free of dust and old film, dust and dirt and other debris to provide fully open capillary system, conducive to the formation of the product penetration and crystals;

◇Of all brushing the products of concrete, must carefully check whether there is a structural defect, such as template rod hole, crack, honeycomb shaped inferior surface, potholes, construction joints interface concave and convex inequality shall be repair chisel, cleaning, caulking, reinforcing, leveling treatment, waterproof construction of large area;

◇Bathroom construction of pipe joints shall be carried out by the special treatment, along the tube wall and the surface junction, chisel 10mm deep V type groove after sealing and waterproof base coating;

◇To ensure that the coating thickness and construction recommended dosage. Brushing method was adopted in the construction, if the stock is too thin, uneven stirring, secondary water, are easy to cause base powder or shell phenomenon;

◇Such as concrete components need to be filled, the construction of 36 hours before the fill wet soil, but can not be filled with dry soil in 7 days, to prevent its waterproof coating.

Storage and transportation:When storing and transporting products, they should be stacked separately according to product type and model, and should not be mixed to prevent moisture.

Reference dosage:For each millimeter of coating film thickness, the amount of paint used is approximately: 2.5kg/㎡-2.8kg/㎡.

Copyright © Nantong Yuru Engineering Materials Co., Ltd. All Rights Reserved