Tel: +86 15051225801

Email: [email protected]

Tel: +86 15051225801

Email: [email protected]

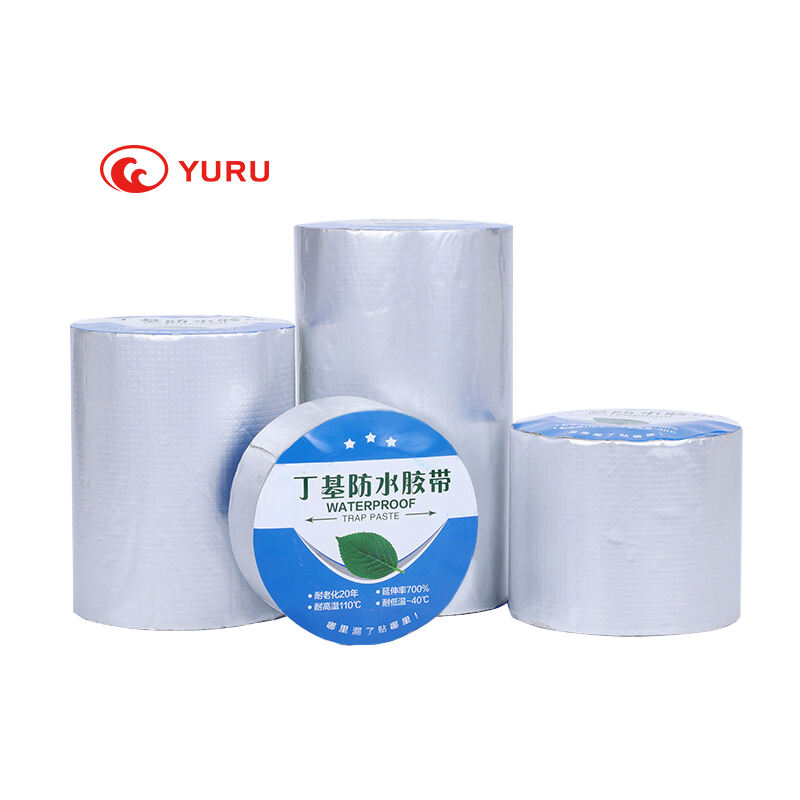

Seemingly simple butyl rubber tape has a much deeper significance in various industries as well on account of its unique features. Produced through processes using isobutylene and small amounts of isoprene, this particular synthetic rubber has capabilities that are waterproofness,strong adhesion as well as durable. This is why it is a widely used option for sealing and weatherproofing. Tape butyl rubber demonstrates its versatility as a multi-use, eco-friendly material that adapts quickly to changing needs in both the broader technological realm and specific industries looking for innovative alternatives.

So far as the building trade is anxious, tape butyl rubber acts amazingly in maintaining constructions watertight and airtight. It has a capability to mold into irregular shapes for use as it conforms in shape and moisture barriers when compressed. And, it is used for windows and door installations making sure there are no drafts or water leak through a building envelope so that your energy efficiency goes up with the lower heat loss. This enables its resistance to UV light, which may have adverse effects outdoors such as ozone and high temperatures: a longer life that results in maintenance savings throughout the years or fewer replacements.

With growing worries regarding the environment, tape butyl rubber offers an advantage in this respect over conventional damp proof course. Tape Butyl rubber is generally solvent free, therefore does not contribute to the release of VOCs into our indoor air quality and harm to the environment so it is a perfect solution for this in terms of sustainability. The longevity of the device saves waste in the long run - a concept that fits perfectly into plans for circular economy. Tape Butyl Rubber for Environmentally Friendly Homeowners Durability that Withstands the Test of TimeWhether placed on a garden throughout all four seasons or to ensure pipe insulation remains flexible, butyl rubber tape persists in defending against rain and sun year after year.

One of the most significant applications for this tape is in vehicle sealing systems with butyl rubber taping. It also contributes to passenger comfort and safety by providing a sealed, secure attachment of windshields and sunroofs that prevents water leaks, muffles shift clicks hyper-locally (see below for more detail on sound deadening properties),eliminates the need for hazardous primers or surface treatments. The suppleness of the application enables it to conform well around all curvatures, so that form a tight seal against wind and projections from flying rocks. In addition, it's lightweight and thus aids in fuel efficiency; an important thing to consider when designing cars today.

Tape butyl rubber has proved to be a boon in the roofing industry. In addition, it is helpful in sealing flashing details, vent pipes and skyrights to protect against roof leaks which can lead cause facia damage or much worse mold formation. It comes with self-adhesive features that simplify the installation procedure, thus saving time and costs over normal methods. In addition, it is UV and extreme weathering resistant for long-lasting performance in any climate. The outcome is roofs that last, protect your investment and reduce repair costs over time.

Copyright © Nantong Yuru Engineering Materials Co., Ltd. All Rights Reserved